8 months

Bones

With so many resources going to waste, how can we think of giving a material a new value or a second life?

Design Research, Materiality Science,

Bio-plastics

Bio-plastics

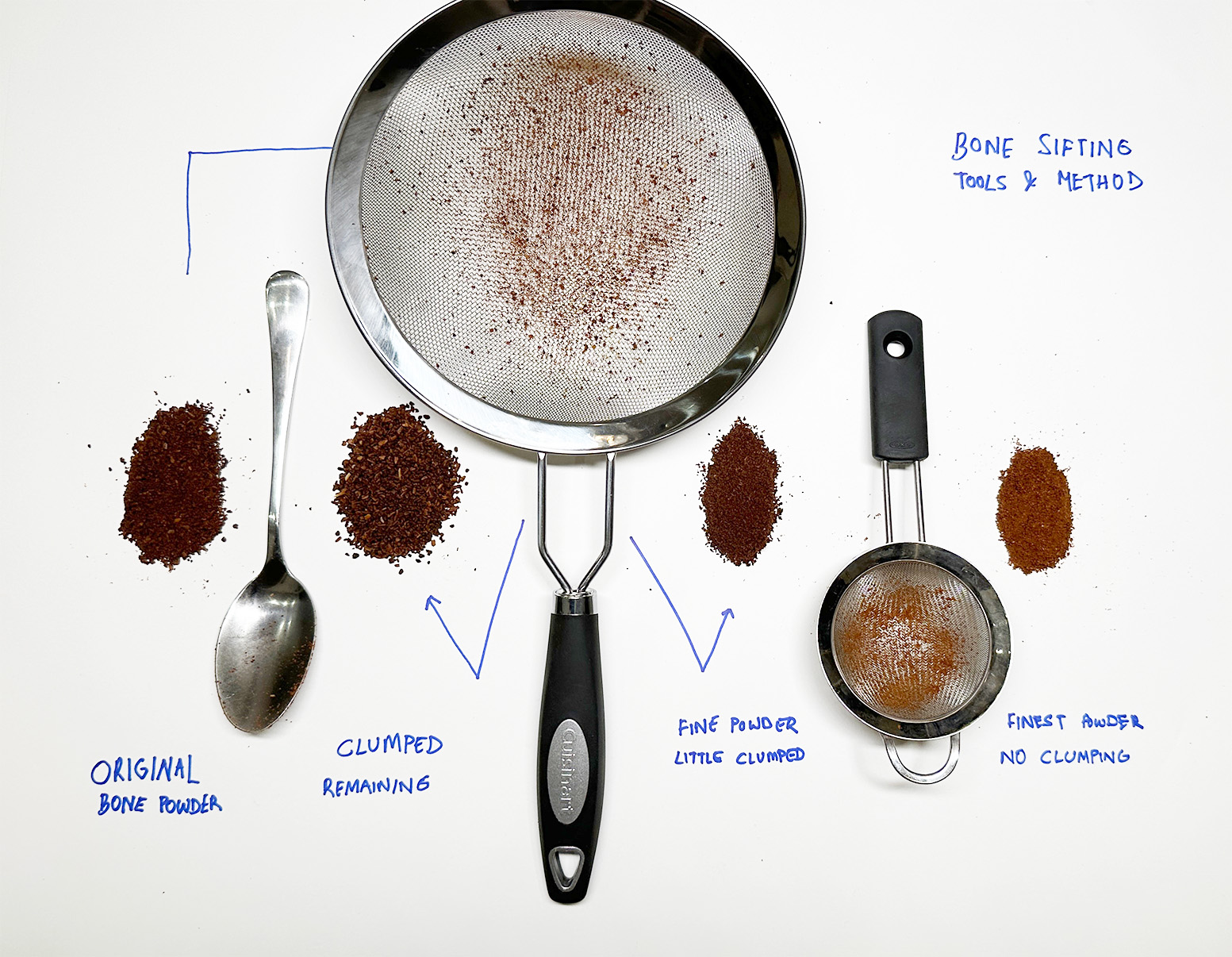

Method

Sourcing local materials was an important aspect of this project. Having a friend that works at a restaurant always works.

The Bones on the right have been individually deskinned, washed, boiled and then baked for 7 hours.

Notes

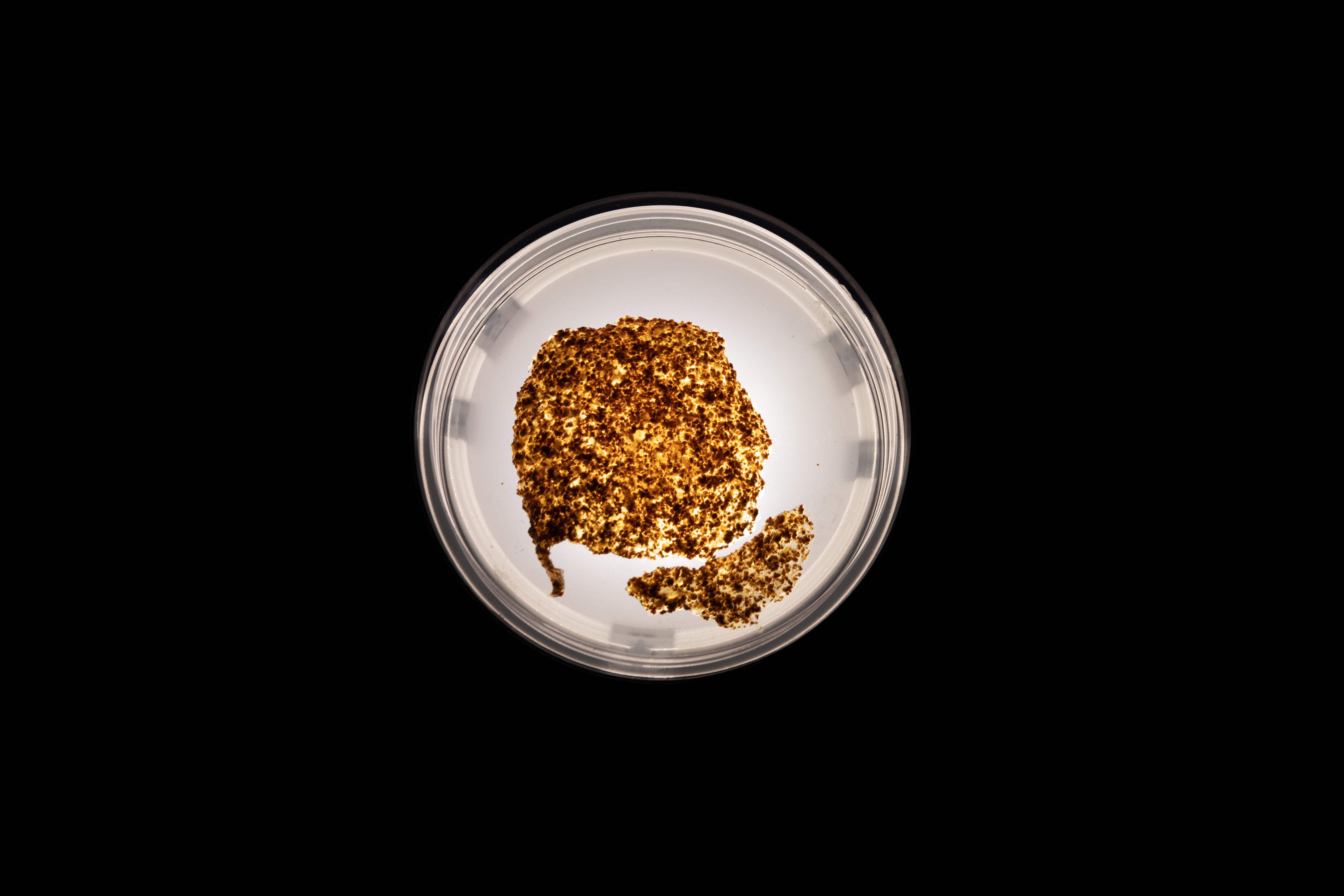

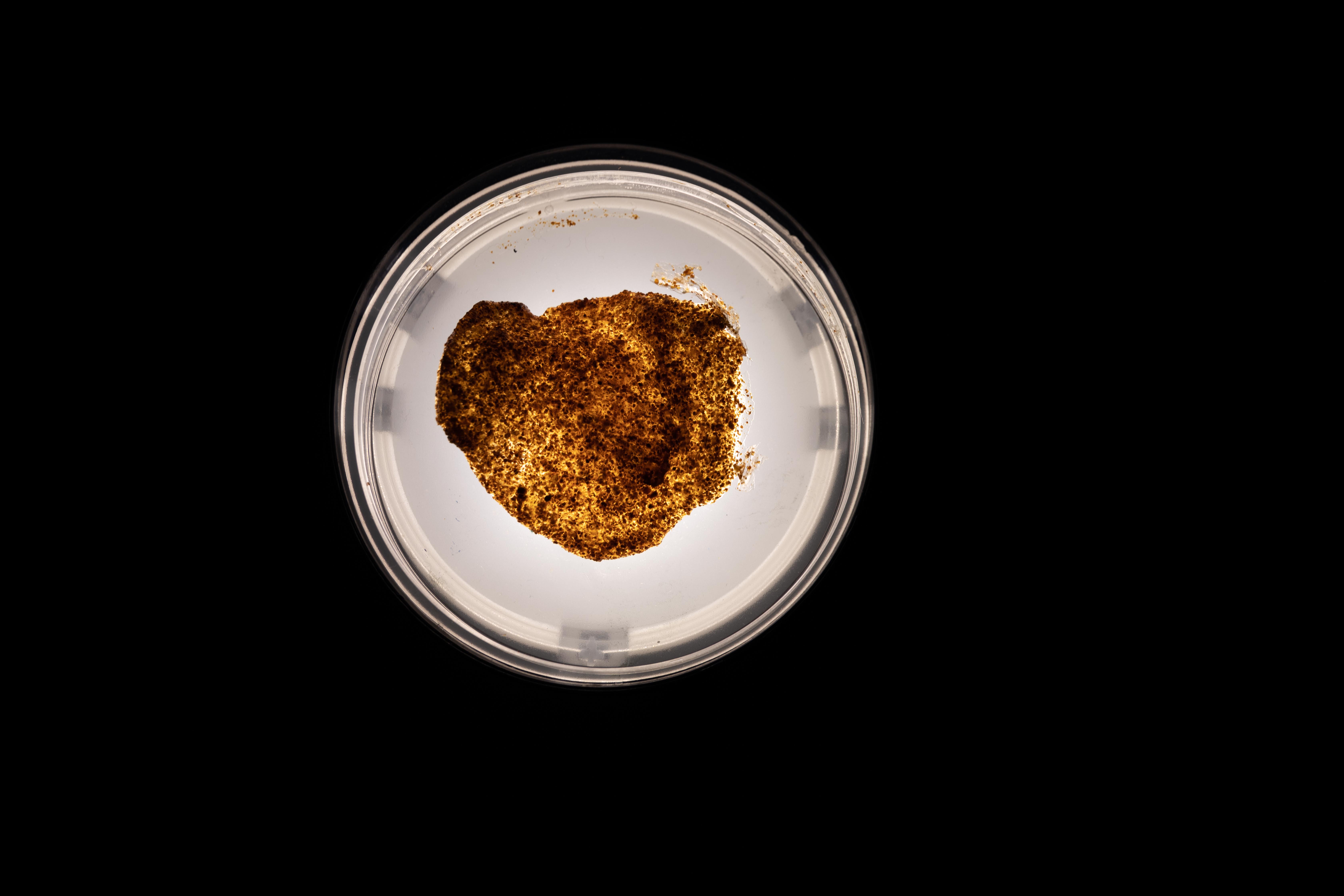

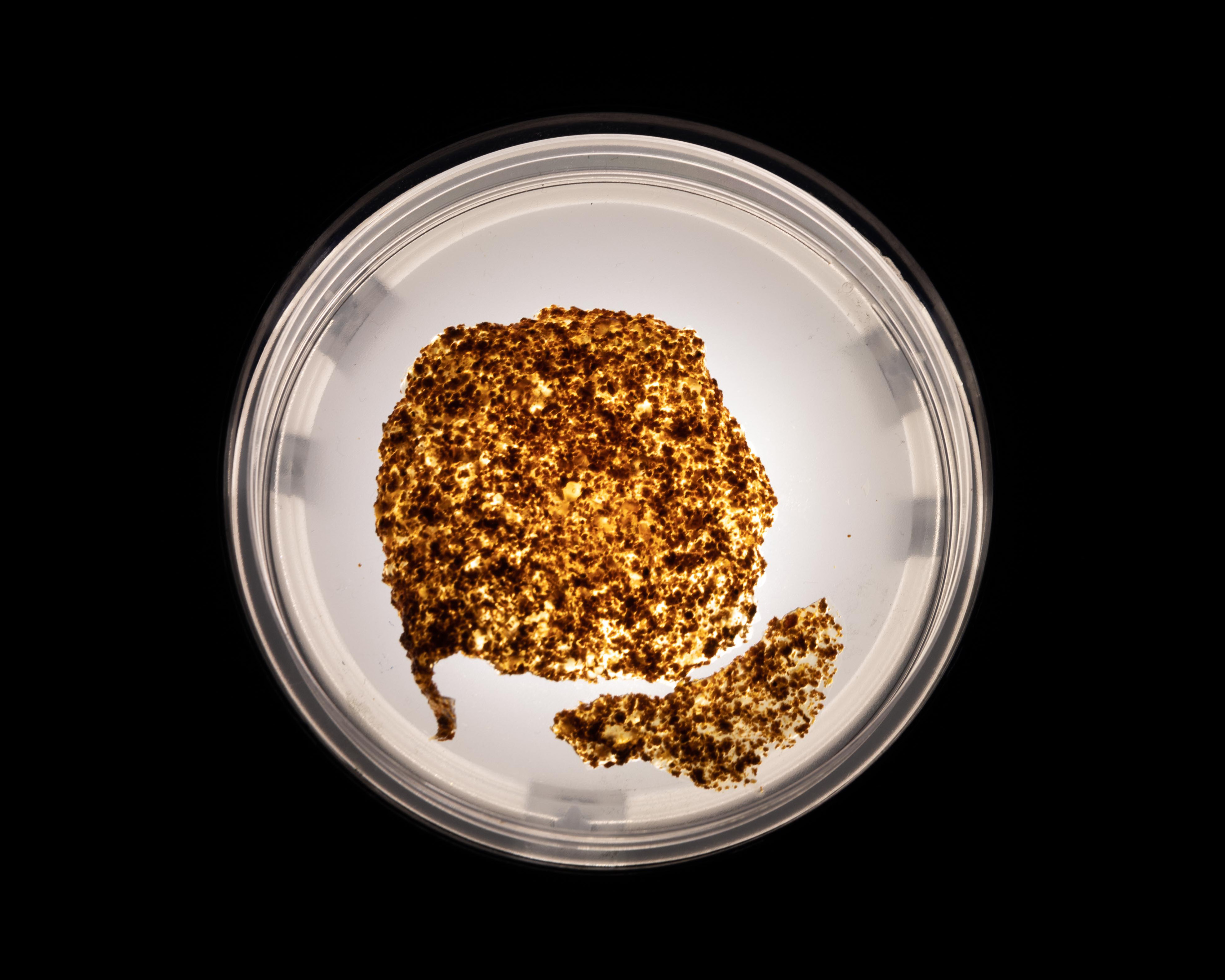

The extruded material was too brittle. There was less binding agent in this sample

Results

Adding Caclium Carbonate aided in binding all the elements together. Making it stronger (not brittle) and sturdy.

Drying time: 3 hours

Drying time: 3 hours

Preceding Experiments

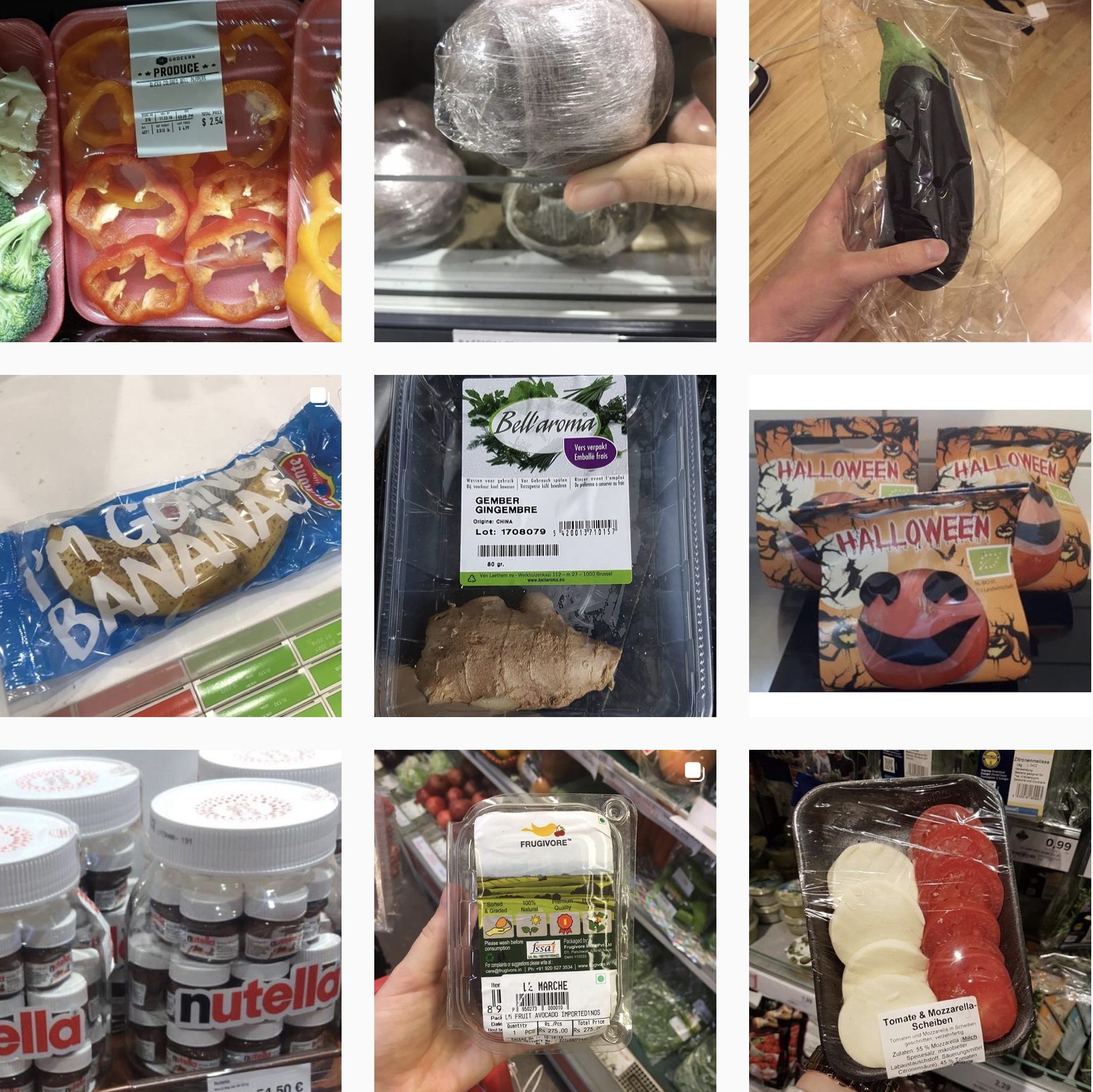

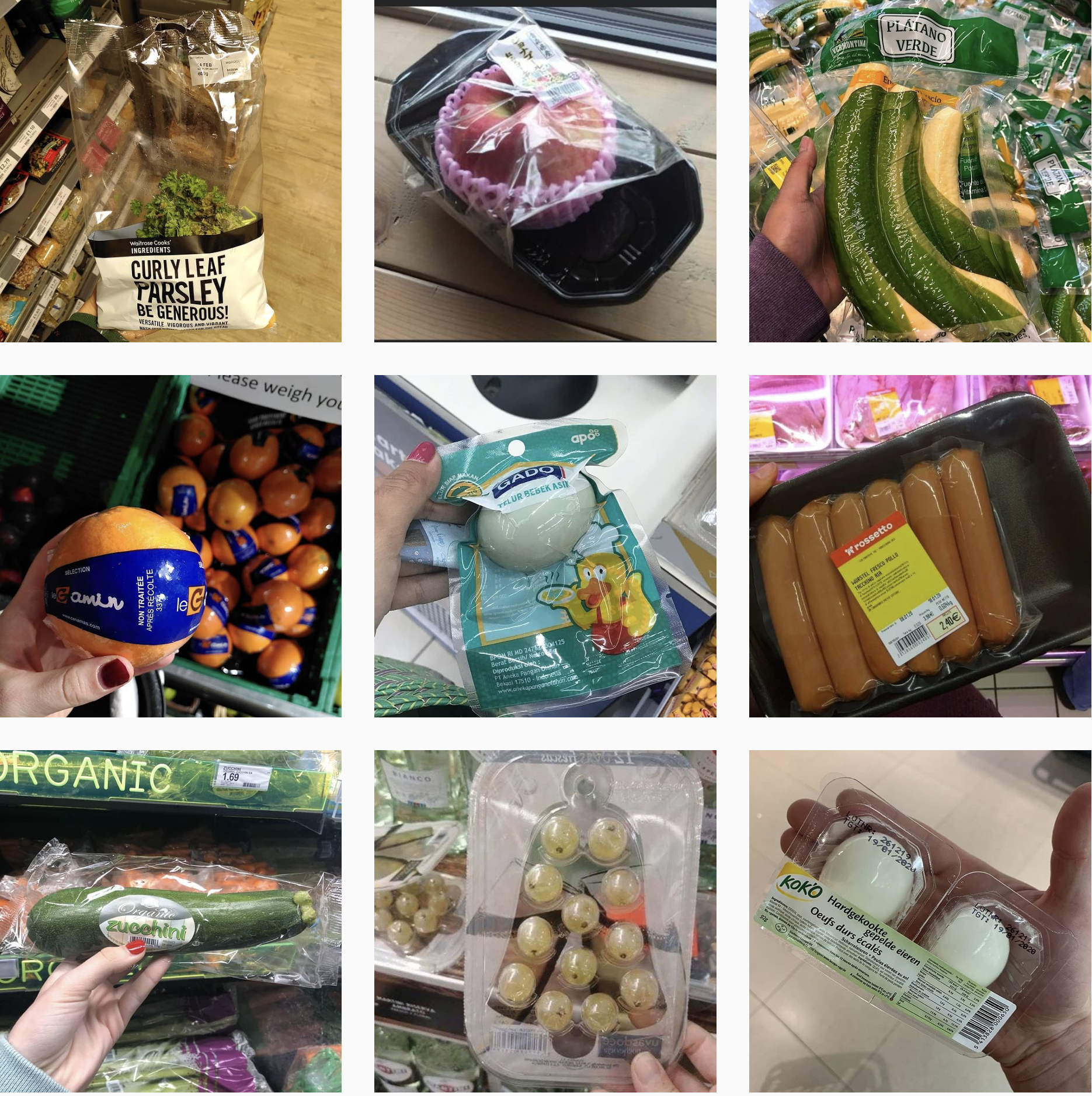

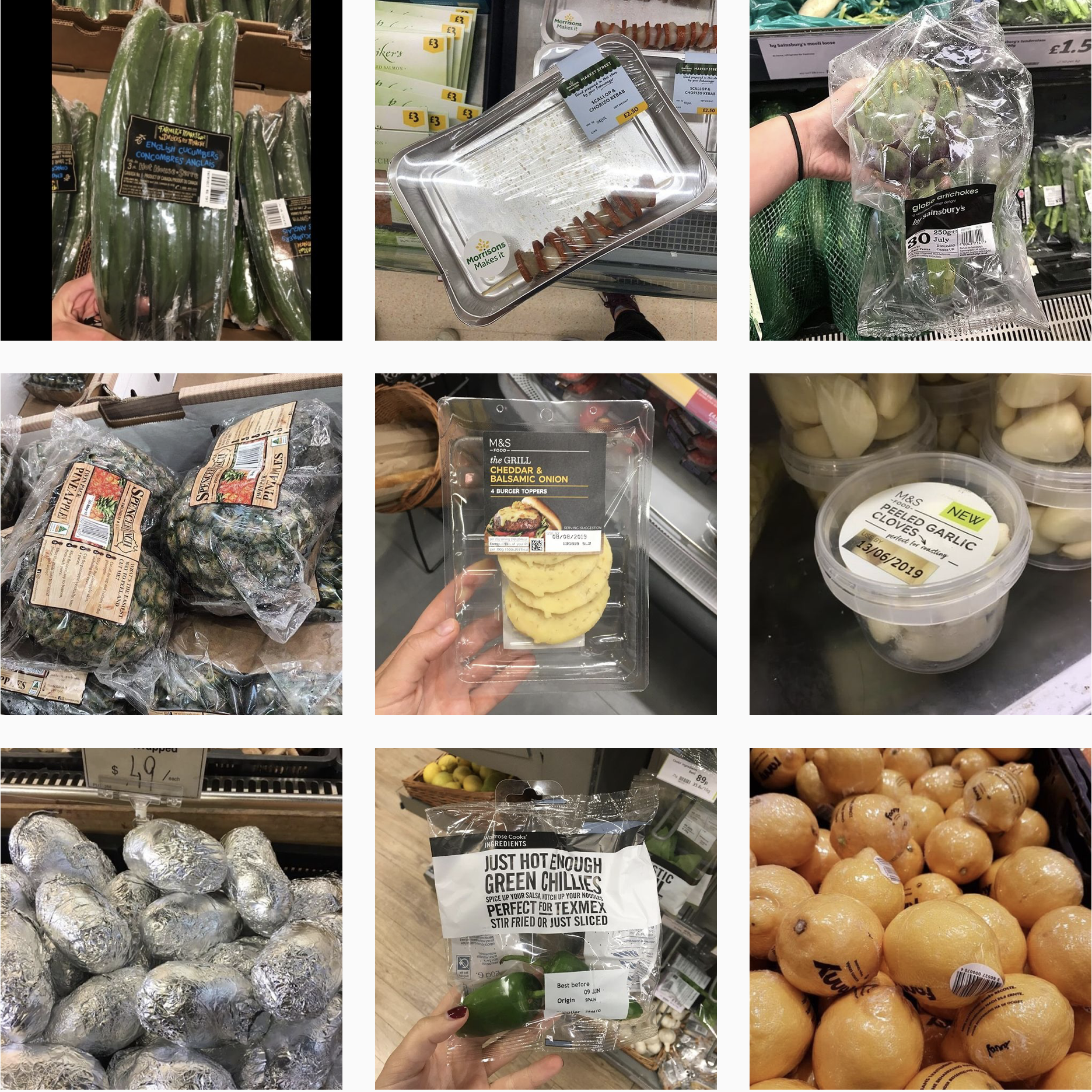

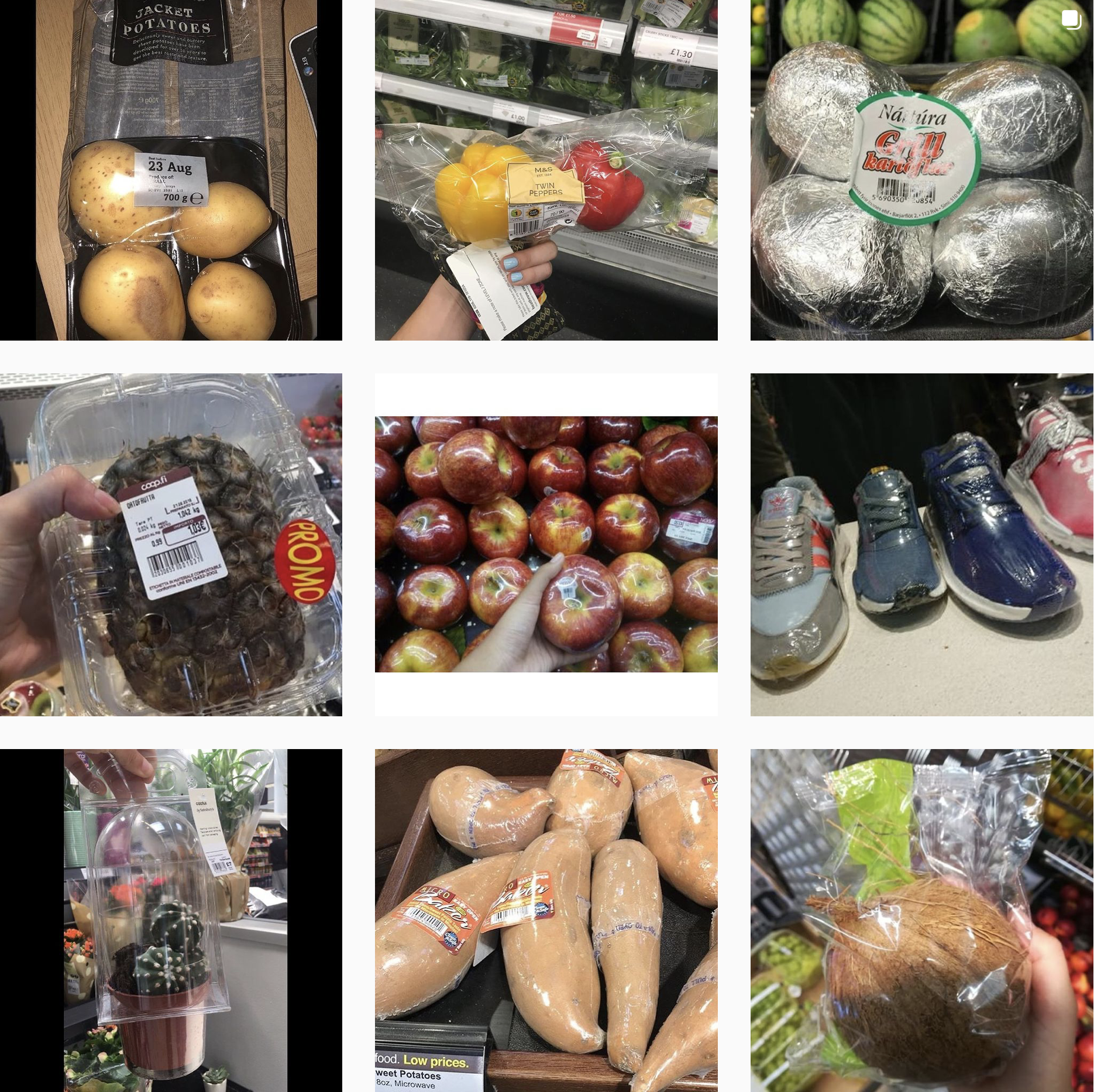

Previously, in response to the plastic waste generated by the food and product industry. How could we use bioplastics in these areas to decrease the burden on the planet?

Background

Using kitchen waste as dye on alganyl to test its properties and speculate its applications as an alternative material. Homes in America produce 43%* of total food waste in the country. I wanted to make sure I was using materials from my kitchen and waste.

I studied the durability, density and strength of the biomaterials through varying its volume through the setting process.

︎︎︎ *How We Fight Food Waste in the US︎︎︎ ,Feeding America.

Natural dyes

Dyeing Alganyl = Glycerin + Agar + water + natural dyes

Followed Fiona Bell & Mirela Alistar’s Alganyl recipe︎︎︎.

I studied the durability, density and strength of the biomaterials through varying its volume through the setting process.

︎︎︎ *How We Fight Food Waste in the US︎︎︎ ,Feeding America.

Natural dyes

- coffee grounds

- strained turmeric

- Orange peels

- dead wilted flowers

- onion peels

- old wilted curry leaves

- strained cinnamon

Dyeing Alganyl = Glycerin + Agar + water + natural dyes

Followed Fiona Bell & Mirela Alistar’s Alganyl recipe︎︎︎.

Applications

With alganyl’s properties of decomposing, recooking and accessibility, I speculate a future where there can be a range of possibilities.

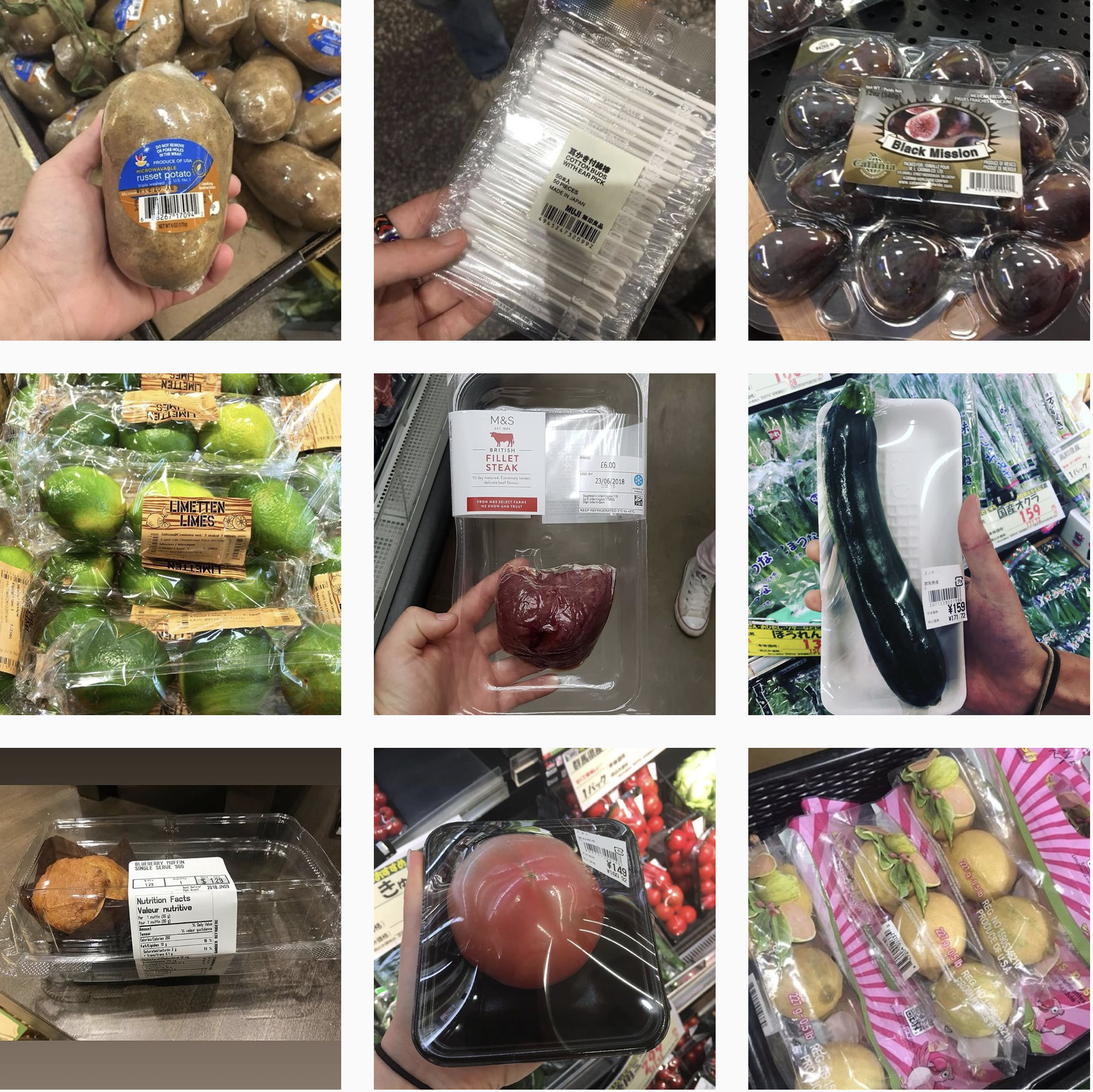

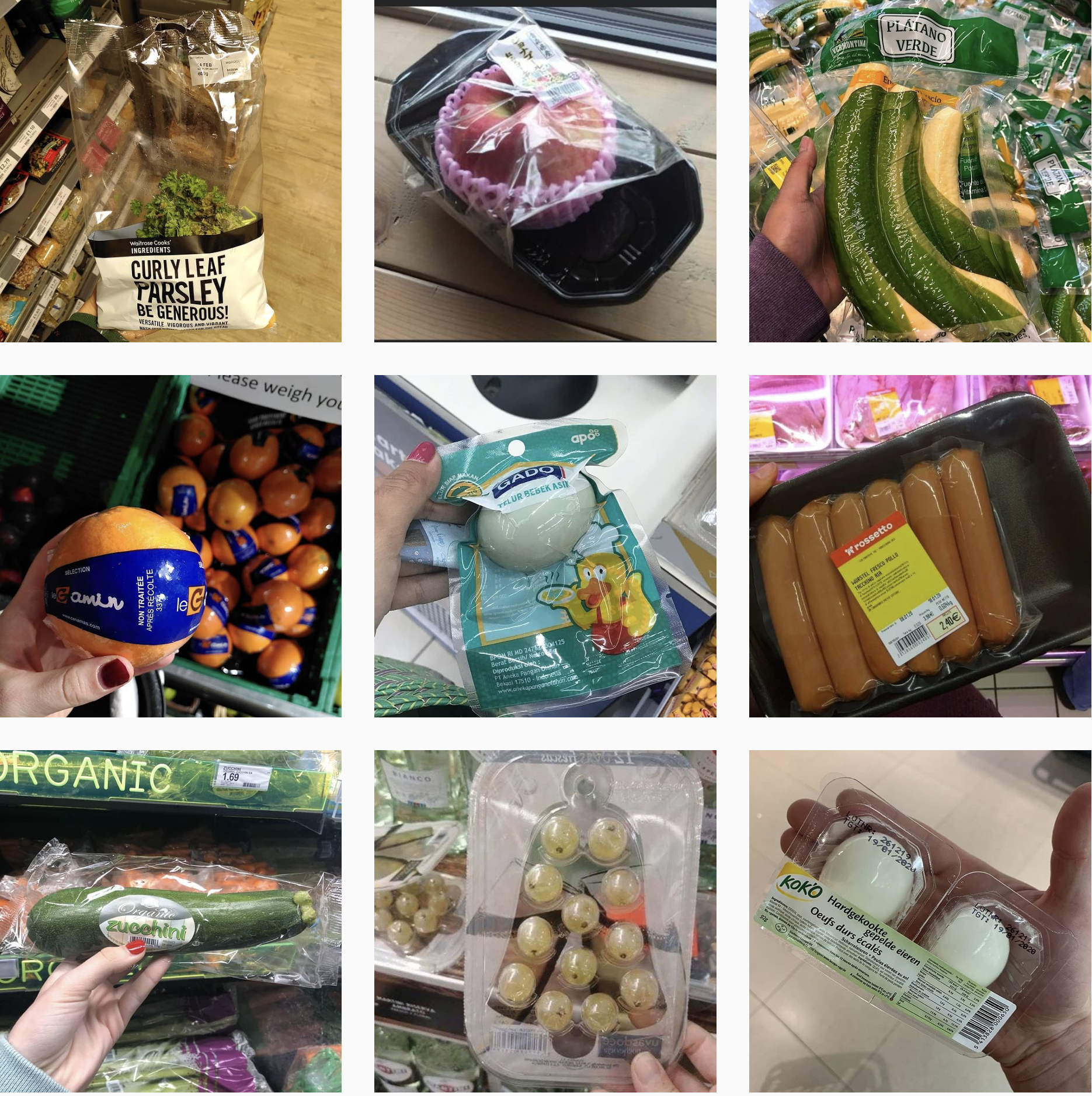

Alganyl as Food Packaging

Most of the fruits and vegetables we buy in the stores come in thin polyethylene sheets which are too thin to recycle, hence end up in landfill.

Since alganyl is water soluble, the packaging would easily dissolve and go down the drain or it can be collected and reheated to recook the material. Alganyls biodegradable propert allows for the material to be thrown away without any harm to the environment.

Since alganyl is water soluble, the packaging would easily dissolve and go down the drain or it can be collected and reheated to recook the material. Alganyls biodegradable propert allows for the material to be thrown away without any harm to the environment.

Alganyl as soap packaging

Soaps generally come in thin plastic wrap whichis then protected by the cardboard box. While thecardboard is recyclable the plastic again ends up inlandfill.

Alganyl can be used in many ways. The bio-plasticcan serve as a soap coaster and wash away aftereach shower. It’s purpose could also be purely asbranding for a product by using it as a fragranceenhancer. My soap is odorless but with the alganyl (dyed with flowers) it has a subtle smell of flowers.

Alganyl can be used in many ways. The bio-plasticcan serve as a soap coaster and wash away aftereach shower. It’s purpose could also be purely asbranding for a product by using it as a fragranceenhancer. My soap is odorless but with the alganyl (dyed with flowers) it has a subtle smell of flowers.

Special Thanks to:

Emily Gordin and Maya Stackhouse, Biomaterial Researchers and Fabricators

Claudette, Restaurant, NYC

Emily Gordin and Maya Stackhouse, Biomaterial Researchers and Fabricators

Claudette, Restaurant, NYC

Resources:

Delgado, Carolina Vasco Costa. “Organic Waste Bio-Based Materials for 3D Extrusion : Eggshells, Shells Sand and Coffee Grains with Sodium Alginate.” Metadados do item. Accessed May 23, 2023. https://oasisbr.ibict.br/vufind/Record/RCAP_1ae2b3c054c76c9c2e67cf3d869236cf.

Copernicus Institute of Sustainable Development, 2014- 2020. Accessed May 23, 2023. https://www.uu.nl/sites/default/files/Report%20Reseach%20Assessment%20Copernicus.pdf.

Karana, Elvin. “Characterization of ‘Natural’ and ‘High-Quality’ Materials to Improve Perception of Bio-Plastics.” Journal of Cleaner Production 37 (2012): 316–25. https://doi.org/10.1016/j.jclepro.2012.07.034.

Geueke, Birgit, and Jane Muncke. “Substances of Very High Concern in Food Contact Materials: Migration and Regulatory Background.” Packaging Technology and Science 31, no. 12 (2017): 757–69. https://doi.org/10.1002/pts.2288.

Kaarianen, Pirjo, Liisa Tervinen, Tapani Vuorinen, Nina Riutta, and Eeva Suorlahti. The chemarts cookbook. Espoo, Finland: Aalto School of Art and Design, 2020.

Camere, Serena, and Elvin Karana. “Fabricating Materials from Living Organisms: An Emerging Design Practice.” Journal of Cleaner Production 186 (2018): 570–84. https://doi.org/10.1016/j.jclepro.2018.03.081.

Delgado, Carolina Vasco Costa. “Organic Waste Bio-Based Materials for 3D Extrusion : Eggshells, Shells Sand and Coffee Grains with Sodium Alginate.” Metadados do item. Accessed May 23, 2023. https://oasisbr.ibict.br/vufind/Record/RCAP_1ae2b3c054c76c9c2e67cf3d869236cf.

Copernicus Institute of Sustainable Development, 2014- 2020. Accessed May 23, 2023. https://www.uu.nl/sites/default/files/Report%20Reseach%20Assessment%20Copernicus.pdf.

Karana, Elvin. “Characterization of ‘Natural’ and ‘High-Quality’ Materials to Improve Perception of Bio-Plastics.” Journal of Cleaner Production 37 (2012): 316–25. https://doi.org/10.1016/j.jclepro.2012.07.034.

Geueke, Birgit, and Jane Muncke. “Substances of Very High Concern in Food Contact Materials: Migration and Regulatory Background.” Packaging Technology and Science 31, no. 12 (2017): 757–69. https://doi.org/10.1002/pts.2288.

Kaarianen, Pirjo, Liisa Tervinen, Tapani Vuorinen, Nina Riutta, and Eeva Suorlahti. The chemarts cookbook. Espoo, Finland: Aalto School of Art and Design, 2020.

Camere, Serena, and Elvin Karana. “Fabricating Materials from Living Organisms: An Emerging Design Practice.” Journal of Cleaner Production 186 (2018): 570–84. https://doi.org/10.1016/j.jclepro.2018.03.081.

︎ Project Song Dedication - PFSJ︎︎︎